MedCenter 5AX

5-AXIS VERTICAL MACHINING CENTER

Specifications

|

Table Size:

|

6.7” (170mm) round dia.

|

|

Travel (X, Y, Z):

|

10” x 13” x 13”(254 x 330 x 330mm)

|

|

Travel(A, C):

|

-120~+120 Degrees/0 ~ 360 Degrees

|

|

Spindle Taper:

|

HSK-E40

|

|

Spindle Speed:

|

300~30,000rpm

|

|

Tool Storage Capacity:

|

40 Pcs.(120 Optional)

|

|

Tool Change Time (T-T):

|

1.5 Sec.

|

|

Rapid Feed (X, Y, Z):

|

2362ipm (60m/min) X & Y, 1969ipm (50m/min) Z

|

|

Rapid Feed (A, C):

|

36,000 deg. /min (100rpm), 72,000 deg./min (200rpm)

|

|

Power Requirement:

|

30KVA

|

Features

- Ideal for ultra-high precision simultaneous 5-axis machining of small medical parts, micro machining

- Positioning Accuracy: ±0.000079” Full Stroke, Repeatability: ±0.000039”

- Compact design fits within a 4′ x 7′ footprint

- Powerful high speed 30,000rpm HSK-E40 25HP Direct Drive Spindle

- 40 tool, fixed pot ATC with maximum tool weight of 4.4Lbs

- High accuracy package – Linear & rotary scales, 67 million pulse encoder technology, 16mm pitch ballscrews

- Optional 12-station APC available (11″ x 11″ (280 x 280mm) table)

Kitamura Mycenter 3xVT

4+1 AXIS VERTICAL MACHINING CENTER

Specifications

|

Rotary Table Size:

|

8.7″ Diameter (220mm)

|

|

w/Full Table Length:

|

11.8″ x 19.7″ (300 x 500mm)

|

|

Travel (X, Y, Z):

|

30.7” x 20.1” x 17.3” (780 x 510 x 439mm)

|

|

Spindle Taper:

|

NST No. 40

|

|

Spindle Speed:

|

15,000rpm, Built-In, Dual Contact

|

|

Tool Storage Capacity:

|

40 Pcs.

|

|

Tool Change Time (T-T/C-C):

|

2.2 Sec. /4.2 Sec.

|

|

Rapid Feed (X, Y, Z):

|

1,890ipm (48m/min)

|

|

Power Requirement:

|

30KVA

|

Features

- Built-in 4th/5th Axis Trunnion Table

- Rigid solid Meehanite cast construction with THK heavy duty cross linear guide ways

- High speed rapids of 1,890ipm (X, Y, Z) boosts work throughput

- High speed, heavy duty 15,000rpm, built-in, 41HP, Dual contact spindle

- Standard base wash system, internal chip augers and scraper type chip conveyor

- Plumbed for coolant thru the spindle (220psi/1000psi option)

- High speed processing Arumatik-Mi Pro control

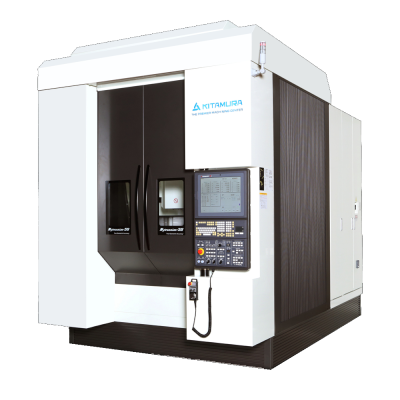

Kitamura MyTrunnion 4G

5-AXIS VERTICAL MACHINING CENTER

Specifications

|

Table Size:

|

15.7” (400mm) round dia.

|

|

Travel (X, Y, Z):

|

24” x 24” x 19.7” (610 x 610 x 500mm)

|

|

Travel (A, C):

|

-120~+30 deg. /0~360 deg.

|

|

Spindle Taper:

|

NST No. 40

|

|

Spindle Speed:

|

40~15,000rpm

|

|

Tool Storage Capacity:

|

60 Pcs. (Opt. 100T)

|

|

Tool Change Time (T-T/C-C):

|

2.2 Sec. /5.8 Sec.

|

|

Rapid Feed (X, Y, Z):

|

1969ipm (50m/min) X & Y, 985ipm (25m/min) Z

|

|

Rapid Feed (A, C):

|

18,000 deg. /min (50rpm)

|

|

Power Requirement:

|

45KVA

|

Features

- Ideal for ultra-high precision simultaneous 5-axis machining

- Positioning Accuracy: ±0.000079” Full Stroke, Repeatability: ±0.000039”

- Sliding overhead door allows for easy workpiece loading/unloading

- Powerful #40, 15,000rpm, 15HP Direct Drive, Dual Contact Spindle Optional HSK-A63 Spindle Configuration available

- Highly Rigid, Ultra-High Precision Roller Gear Cam Table in the 4th & 5th Axes

- Expansive 21.7″Dia. x 15.7″H (550 x 400mm) work envelope beats the competition

- Highest grade meehanite cast iron construction for superior vibration absorption and improved surface finishes

Kitamura MyTrunnion 5G

5-AXIS VERTICAL MACHINING CENTER

Specifications

|

Table Size:

|

24.8” round (630mm dia.)

|

|

Travel (X, Y, Z):

|

32” x 29.3” x 19.7” (815 x 745 x 500mm)

|

|

Travel (A, C):

|

-120~+30 deg. /0~360 deg.

|

|

Spindle Taper:

|

NST No. 40

|

|

Spindle Speed:

|

20~20,000rpm

|

|

Tool Storage Capacity:

|

50 Pcs. (100 Opt.)

|

|

Tool Change Time (T-T/C-C):

|

2.5 Sec. /5.0 Sec.

|

|

Rapid Feed (X, Y, Z):

|

1969ipm (50m/min) X & Y, 984ipm (25m/min) Z

|

|

Rapid Feed (A, C):

|

2,000 deg. /min, 6,000 deg. /min

|

|

Power Requirement:

|

45KVA

|

Features

- Ideal for ultra-high precision simultaneous 5-axis machining

- Positioning Accuracy: ±0.000039” Full Stroke, Repeatability: ±0.00002”

- Sliding overhead door allows for easy workpiece loading/unloading

- Powerful 4-step geared spindle delivers high torque and high speed for maximum machining flexibility

- Linear scale feedback on all axes, A & B axis rotary scales

- Highest grade meehanite cast iron construction with solid box ways

Kitamura Supercell 300G

5-AXIS HORIZONTAL MACHINING CENTER

Specifications

|

Table Size:

|

7.9” (200mm) Round

|

|

Travel (X, Y, Z):

|

18.1” x 20.1” x 18.1”(460 x 510 x 460mm)

|

|

Travel (A, B):

|

-120 to +30 deg. /0~360 deg.

|

|

Spindle Taper:

|

NST No. 40

|

|

Spindle Speed:

|

200~20,000rpm

|

|

Tool Storage Capacity:

|

174 Pcs. (230,258,314 Opt.) Matrix Style

|

|

Tool Change Time(T-T/C-C):

|

1.3 sec. /2.5 sec.

|

|

Rapid Feed (X, Y, and Z):

|

2,362ipm (60m/min)

|

|

Rapid Feed (A, B):

|

18,000 deg./min (50rpm)

|

|

Power Requirement:

|

55KVA

|

Features

- Horizontal configuration allows flexibility for single set-up, unmanned machining

- Ultra high positioning Accuracy: ±0.000079”/full stroke, Repeatability: ±0.000039”

- Ideal for both unmanned one-off and high quantity production

- Standard 20-station automatic pallet changer with up to 80 pallets available as an option

- Highest grade Meehanite cast iron construction with heavy duty roller linear guide way system

- High speed, built-in, dual contact 20,000rpm spindle

- Work handling system reduces pallet load & unload time, allowing for just-in-time operation

Kitamura Supercell 400G

5-AXIS HORIZONTAL MACHINING CENTER

Specifications

|

Table Size:

|

13.8” (350mm) Round

|

|

Travel (X, Y, Z):

|

20.1” x 20.1” x 20.1” (510 x 510 x 510mm)

|

|

Travel (A, B):

|

-120~+30 deg. /0~360 deg.

|

|

Spindle Taper:

|

NST No. 40

|

|

Spindle Speed:

|

20~20,000rpm

|

|

Tool Storage Capacity:

|

140 Pcs. (190, 290 Opt.)

|

|

Tool Change Time (T-T/C-C):

|

2.1 sec. /5.0 sec.

|

|

Rapid Feed (X, Y, and Z):

|

1969ipm (50m/min)

|

|

Rapid Feed (A, B):

|

2,400deg./min (6.7rpm)/12,000deg./min (33.3rpm)

|

|

Power Requirement:

|

45KVA

|

Features

- Horizontal configuration allows flexibility for single set-up, unmanned machining

- Ultra high positioning Accuracy: ±0.000039”/full stroke, Repeatability: ±0.00002”

- Ideal for both unmanned one-off and high quantity production

- Standard 20-station automatic pallet changer with loading/unloading station (up to 120 pallets optional)

- Highest grade Meehanite cast iron construction with solid box ways

- Energy saving, high performance, high speed 20,000rpm, 4-step gear driven, dual contact spindle ensures rigidity

- Work handling system reduces pallet load & unload time, allowing for just-in-time operation