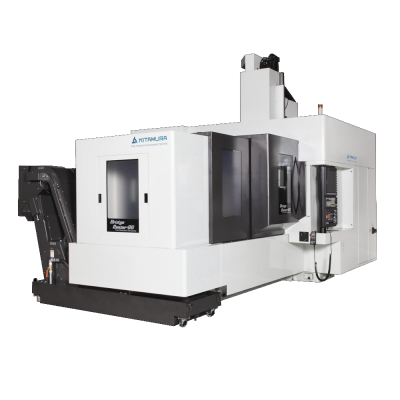

Kitamura Bridgecenter 6G (40 & 50 Taper)

DOUBLE COLUMN MACHINING CENTER

Specifications

|

Table Size:

|

35.4” x 70.9” (900 x 1,800mm)

|

|

Travel (X, Y, Z):

|

60.2” x 43.1” x 28.0” (1,530 x 1,095 x 710mm)

|

|

Spindle Taper:

|

NST No. 40

|

|

Spindle Speed:

|

20~20,000rpm Gear Drive, 4-Step

|

|

Tool Storage Capacity:

|

40 Pcs. (60, 80 Opt.)

|

|

Tool Change Time (T-T/C-C):

|

6.6 Sec. /12 Sec.

|

|

Rapid Feed (X, Y, Z):

|

945ipm (24m/min)

|

|

Power Requirement:

|

35KVA

|

Features

- Ideal for parts requiring heavier cutting loads and higher levels of precision and accuracy. Excellent for Die/Mold applications.

- Positioning Accuracy: ±0.000078”/Full Stroke, Repeatability: ±0.000039”

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #40, high speed, heavy duty 20,000rpm, 4-Step Geared, Dual Contact Spindle

- Double column design provides expansive work envelope and superior rigidity

- Linear scale feedback in X, Y, Z axes

- Space saving footprint takes up only 166 total square feet

- 6,600Lb table capacity

Kitamura Bridgecenter 8G

DOUBLE COLUMN MACHINING CENTER

Specifications

|

Table Size:

|

35.4” x 98.4” (900 x 2,500mm)

|

|

Travel (X, Y, Z):

|

80.0” x 43.1” x 28.0” (2,032 x 1,095 x 710mm)

|

|

Spindle Taper:

|

NST No. 50

|

|

Spindle Speed:

|

35~12,000rpm Gear Drive, 4-Step

|

|

Tool Storage Capacity:

|

40 Pcs. (60, 80 Opt.)

|

|

Tool Change Time (T-T/C-C):

|

6.6 Sec. /12 Sec.

|

|

Rapid Feed (X, Y, Z):

|

945ipm (24m/min)

|

|

Power Requirement:

|

45KVA

|

Features

- Ideal for parts requiring heavier cutting loads, and parts that require a higher level of precision and accuracy.

Excellent for Die/Mold applications. - Positioning Accuracy: ±0.000078”/Full Stroke, Repeatability: ±0.000039”

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #50, High Speed, High torque 12,000rpm, Dual Contact, 4-Step Gear Driven Spindle

- Double column design with patented triangular crossbeam provides expansive work envelope and superior rigidity when compared with C-Frame style machines

- Linear scale feedback in X, Y, Z axes

- Space saving and compact, the Bridgecenter-8G measures only 137.6″ x 230.9″ (3,494 x 5,866mm) on your floor!

- 7,700 Lb table capacity allows for the capacity to machine larger and heavier work pieces

Kitamura Bridgecenter 10G

DOUBLE COLUMN MACHINING CENTER

Specifications

|

Table Size:

|

53.9” x 118.1” (1,370 x 3,000mm)

|

|

Travel (X, Y, Z):

|

100.0” x 63.6” x 31.5” (2,540 x 1,615 x 800mm)

|

|

Spindle Taper:

|

NST No. 50

|

|

Spindle Speed:

|

35~12,000rpm Gear Drive, 4-Step

|

|

Tool Storage Capacity:

|

40 Pcs. (60, 80 Opt.)

|

|

Tool Change Time (T-T/C-C):

|

6.6 Sec. /14 Sec.

|

|

Rapid Feed (X, Y, Z):

|

945ipm (24m/min)

|

|

Power Requirement:

|

50KVA

|

Features

- Well suited for large part machining requiring increased rigidity and higher levels of precision and accuracy. Perfect for roughing and finishing of large cavities and cores in the die/mold industry.

- Positioning Accuracy: ±0.000078” Full Stroke, Repeatability: ±0.000039”

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #50, Gear Driven, High Speed, High Torque 12,000rpm Dual Contact Spindle

- Patented double column bridge type design provides expansive work envelope and superior rigidity

- Linear scale feedback in X, Y, Z axes

- Ultra high speed and high precision contour control for smoother and faster machining.2,800 block/sec. processing speeds

- 13,300 Lb table capacity provides added benefits for larger, heavier, more powerful machining

Kitamura Bridgecenter 12G

DOUBLE COLUMN MACHINING CENTER

Specifications

|

Table Size:

|

53.9” x 137.8” (1,370 x 3,500mm)

|

|

Travel (X, Y, Z):

|

120.0” x 63.6” x 31.5”

(3,050 x 1,615 x 800mm) |

|

Spindle Taper:

|

NST No. 50

|

|

Spindle Speed:

|

35~12,000rpm Gear Drive, 4-Step

|

|

Tool Storage Capacity:

|

40 Pcs. (60, 80 Opt.)

|

|

Tool Change Time (T-T/C-C):

|

6.6 Sec. /14 Sec.

|

|

Rapid Feed (X, Y, Z):

|

945ipm (24m/min)

|

|

Power Requirement:

|

50KVA

|

Features

- 120″ extended X-Axis stroke offers flexibility in large part processing that requires increased levels of rigidity and higher levels of precision and accuracy.

- Positioning Accuracy: ±0.000078” Full Stroke, Repeatability: ±0.000039”

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #50, Gear Driven, High Speed, High Torque 12,000rpm Dual Contact Spindle

- Patented double column bridge type design provides expansive work envelope and superior rigidity

- Linear scale feedback in X, Y, Z axes

- A unique optional 5-axis articulating head can be incorporated for multi angle, complex part machining made easy

- 13,300 Lb table capacity provides added benefits for larger, heavier, more powerful machining